Designed to meet diverse application and operational requirements, the standard L-shaped two-component mixing head achieves consistently excellent quality in practice. The key feature of all standard L-shaped two-component mixing heads is the L-shaped mixing chamber, composed of two cylindrical chambers of varying sizes, each housing a large and small piston.

In the smaller diameter chamber (mixing chamber), two corresponding nozzles are geometrically opposed. High-speed, turbulent jets from the dual-angled jets impact each other, achieving optimal mixing.

The larger diameter chamber, connected at a 90-degree angle to the smaller mixing chamber, serves as the conduit for raw material infusion. The high-speed turbulent flow thoroughly mixes the components upon transitioning from the first mixing chamber. This flow exits the mixing head in a laminar, non-splashing manner. After infusion, the piston provides self-cleaning.

The large piston rod's stopper is also adjustable, adjusting its position changes the extent of the large piston rod's coverage of the mixing chamber. This allows for the controlled release of the mixture from the mixing chamber, thereby adjusting both the quality and rate of the mix.

LFH18 Four-Component Foam Gun Advantages:

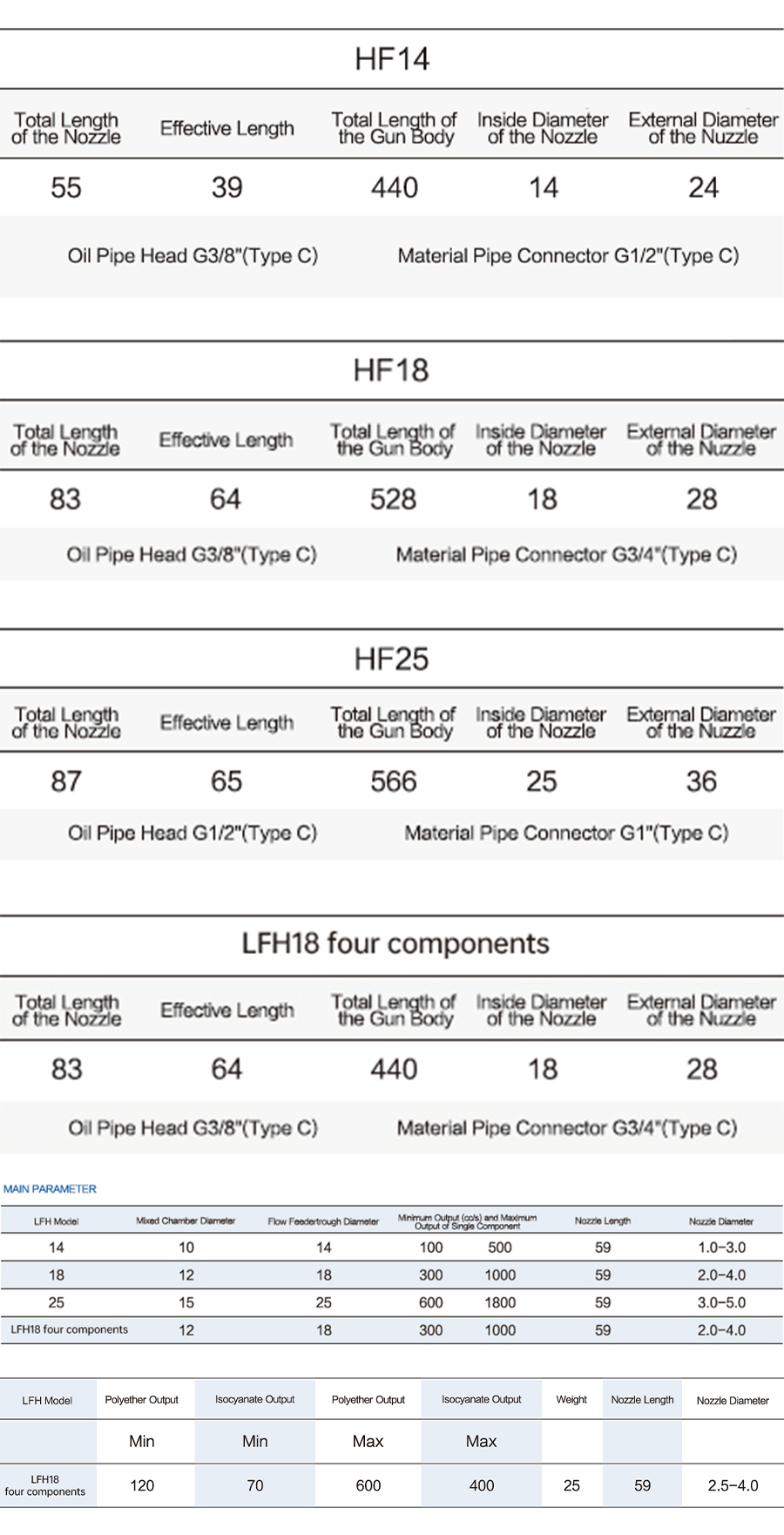

Industry demand for foam guns capable of handling multiple formulations is increasing. We developed the LFH18 four-component series of mixing heads to meet this market need.

This mixing head features an L-shaped mixing chamber with two independent mixing chambers, each ultimately filled through a single outlet. The two mixing chambers are fed by two independent metering devices (e.g., two different isocyanates and two different polyethers) or a single three-component device (two different polyethers and one isocyanate, with an automated electronically controlled valve switching the two mixing chambers). This allows two different formulations to be applied simultaneously to the same or different molds, producing dual-density foams, widely used in automotive seat cushion production lines.